Construction projects are complex. They involve numerous moving parts. When mechanical, electrical, and plumbing (MEP) systems are not planned together from the outset, problems arise. Pipes clash with beams. Wires get rerouted. Teams scramble to fix issues on-site. Costs rise. That is why early MEP Coordination matters. It helps teams spot problems before they build. With the right MEP coordination services, you avoid delays and reduce waste. That means your project stays on track. It is not just a technical step—it is a smart way to work.

This blog examines why early MEP coordination is crucial in maintaining project timelines and reducing costs.

Here is what you need to know.

The Cost of Getting MEP Wrong

Real-World Failures from Poor Coordination

That stat checks out.

Poor coordination between MEP systems leads to rework. According to SmartCADD’s guide on MEP coordination, this can cause up to 20% of project delays. That is a big setback, especially when it is avoidable. Planning these systems early is not just helpful. It is necessary.

What Is MEP Coordination?

Planning the integration of MEP systems into a building is known as MEP coordination. These systems need to work together without getting in each other’s way. Failure to align them early results in problems later on, such as

- Pipes colliding with ducts

- Wires obstructing airflow

- Teams are wasting time repairing them on-site

Here is what each system does:

- Mechanical systems include heating. They also cover ventilation and air conditioning. These control temperature and airflow for the best indoor air quality.

- Electrical systems manage power throughout the building. They include lighting, outlets, and switches. These systems also support equipment connections. Wiring and distribution panels make it all work

- Plumbing systems carry clean water into the building. They also remove wastewater through drainage lines. Some plumbing setups include fire protection systems. That often means sprinklers and related piping.

MEP coordination makes sure everything fits the building’s structure, follows building codes, and keeps the project moving.

For a deeper dive into the full coordination process, check out our Complete Guide to MEP Coordination in Building Projects.

Why Early Coordination Changes Everything

Benefits of Early MEP Coordination

Early MEP coordination helps teams avoid problems before they start. When MEP systems are planned from the beginning, everything fits better. There is less confusion and fewer delays, which helps to decrease costs.

Here’s what early coordination improves:

- It decreases design conflicts. Systems do not clash. Ducts, pipes, and wires have space to work properly.

- Less rework and fewer cost overruns. Teams do not waste time fixing mistakes on-site.

- With better system integration, HVAC, electrical, and plumbing work as one connected setup.

- Crews follow clear plans. Work moves faster and stays on track.

Using MEP coordination services and MEP clash detection services early in the process makes a real difference. It is not just about avoiding problems; it is about building smarter from the start.

Comparing early vs late coordination outcomes

| Aspect | Early MEP Coordination | Late MEP Coordination |

| Design Conflicts | Identified and resolved during planning | Discovered on-site, causing delays |

| Rework | Minimal—issues are caught early | Frequent—requires redesign and reinstallation |

| Cost Impact | Controlled budget with fewer surprises | Cost overruns due to last-minute fixes |

| System Integration | Seamless—HVAC, electrical, and plumbing work together | Disjointed—systems compete for space |

| Construction Workflow | Streamlined—clear plans and fewer interruptions | Disrupted—teams wait for clash resolution |

| Compliance with Codes | Easier to meet building codes and standards | Risk of non-compliance and failed inspections |

| Use of MEP Services | Strategic—uses MEP coordination and clash detection | Reactive—uses services to fix problems after they occur |

Stakeholders Who Must Be Involved Early

MEP coordination works best when the right people are involved early. If key teams aren’t part of the planning, things get missed. Architects, engineers, contractors, and MEP specialists all need to be in the loop from the start. It helps everyone understand the layout and the limitations. They also came to know how each system fits into the bigger picture. Early input helps avoid confusion in the future.

- Architects need to know how the systems will fit into the design. If they are looped in late, layouts get redrawn.

- Engineers help make sure systems do not interfere with structural elements or site conditions.

- Contractors understand how things get built. Their input helps avoid plans that look good on paper but do not work on-site.

- MEP specialists plan the details—ducts, wiring, pipes—and spot clashes before they happen.

How BIM & 3D Modeling Solve the Problem

BIM MEP Coordination in Action

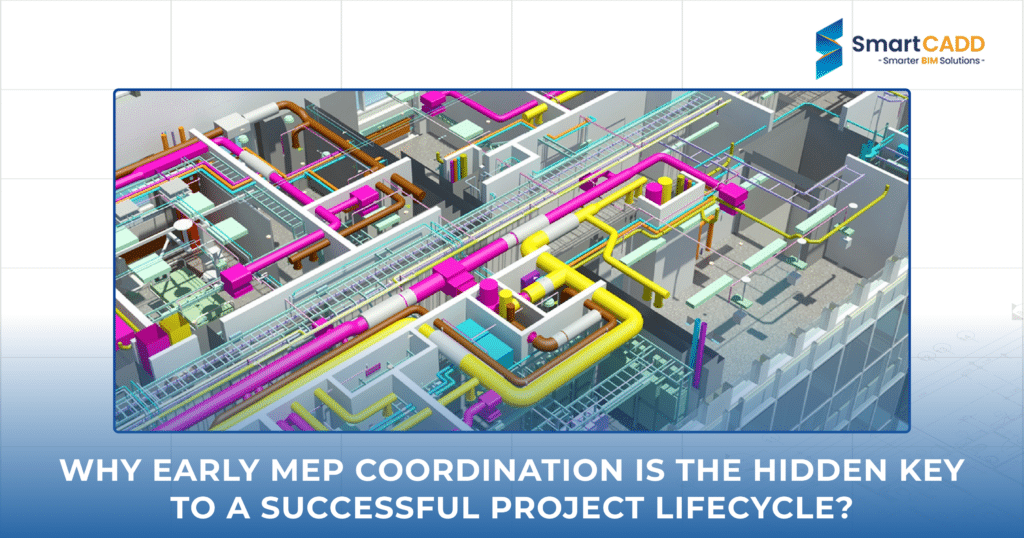

MEP 3D modeling starts in Revit, where engineers build detailed models of

- HVAC

- Electrical

- Plumbing

- Fire protection systems

These models are intelligent as they carry data about dimensions and materials. They also include performance details for each system. This is the foundation of Building Information Modeling (BIM).

Once the models are built, they are exported to Navisworks. That is where coordination happens.

To understand how MEP services integrate seamlessly within BIM workflows, explore our MEP Services and Its Role in BIM Services.

How Revit and Navisworks Work Together

- Modeling in Revit

Engineers create system layouts with full 3D visualization. Each duct, pipe, and cable is modeled with actual dimensions. This helps ensure everything fits in the real building space.

- Aggregation in Navisworks

All models—architectural, structural, and MEP—are combined into one environment. This lets teams see how systems interact in the actual building space.

- Clash Detection Software

Navisworks runs automated checks to find conflicts. For example, a duct running through a beam or a pipe overlapping with an electrical conduit. These clashes are flagged and tracked.

- Issue Resolution

Teams review clashes, assign them to the right stakeholders, and update the Revit model. This loop continues until the model is clash-free.

Watch BIM Clash Detection in Action

Want to show how this works visually? A short demo can highlight how clashes are found and fixed in real time.

Clash Detection with Revit and Navisworks

3D MEP Coordination for Complex Projects

In complex buildings, MEP systems are tightly packed. There is little room for error. Hospitals, data centres, and high-rises need careful planning to avoid clashes and delays.

3D MEP coordination helps teams model MEP systems before construction starts. Using BIM tools, teams can see how systems fit together. They spot problems early and fix designs before construction starts.

Where It’s Most Useful

- Hospitals: Systems like HVAC, medical gas, and power need careful planning. Each one must be placed with precision to avoid issues later. A small mistake can affect patient care.

- Data Centres: Cooling, power, and fire protection systems must be coordinated. Each system relies on the others to keep things working. The building can not afford to shut down.

- High-Rise Buildings: Each floor has tight spaces, so mistakes can not happen. Stacked services make careful coordination essential.

Make Coordination a Priority

Step-by-Step Early Coordination Workflow

❶ Kickoff meeting with all stakeholders

The process starts with a full-team meeting that includes,

- Architects

- Engineers

- Contractors

- MEP specialists

They agree on goals, deadlines, and roles. This is where teams agree on what is expected and talk through site limits. Everyone leaves with a clear plan.

❷ Integrated design using BIM tools

Once the team is agreed, the design begins in Revit. The MEP system is built in 3D with real measurements. These models are combined into one shared layout so everyone works from the same plan, reducing confusion.

❸ Weekly clash detection reviews

Models are imported into Navisworks for clash detection. The software checks for overlaps like

- A pipe running through a beam

- A duct is blocking a light fixture

Clashes are spotted and sent to the right team to fix. Weekly checks help identify problems early and keep things on track.

❹ Final sign-off before construction

Once clashes are fixed and everyone agrees, the model is ready to build from. Final sign-off makes sure the build matches the plan. No unexpected changes on-site.

Learn how effective MEP design and drafting contribute to better building performance in our blog on How MEP Design and Drafting Improve Building Efficiency.

Choosing the Right MEP Coordination Partner

These systems’ coordination is not just about software; it is about clear communication and knowing how to manage complex systems. The right partner helps avoid delays and reduce rework to keep your project on track.

What to Check

- Experience

Have they handled high-rise buildings like hospitals and data centers? These projects demand real-world coordination skills. - BIM Skills

Can they deliver accurate MEP BIM modeling services using tools like Revit and Navisworks? Do they know how to run clash checks and manage shared models? - Past Projects

Ask for examples. Look at how they solved problems and how the final build matched the plan.

Summing Up

Picking the right MEP coordination partner isn’t a quick task. It shapes how your entire project runs. In complex projects, even small errors can cause major delays. That is why experience matters. You need a team that understands

- How systems interact

- How space constraints affect layout

- How to keep everyone aligned from design to construction

It is not just about using BIM tools. It’s about using the tools in real projects. Talking clearly and taking responsibility matter just as much as technical know-how.

If you want a team that has done this before and knows how to get it right, SmartCADD is the best choice.

Why SmartCADD Works

SmartCADD brings clarity to MEP Coordination. Our team knows BIM inside out and has worked on tough projects across sectors. We focus on precision and clear collaboration. If you need reliable MEP BIM modeling services, SmartCADD is built for it.